|

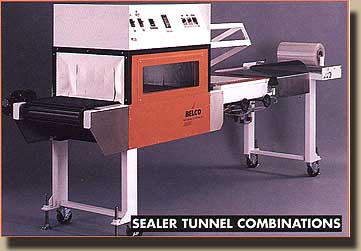

Belco Sealer- Tunnel Combinations The Solid Framework for Productivity |

Total Efficiency... No Ifs, Ands or Bolts

You'll profit from the solid advantages of Belco's Model STC

Sealer-Tunnel Combinations. These ruggedly-built machines provide the

framework for greater productivity and less maintenance, which means

higher profitability for you. Belco's durable, heavy-duty, fullywelded

tubular steel frames give you dependable performance and consistent

results, even after years of hard use.

Belco's STCs are built to last. No bolts to loosen and weaken the

machine. No shaking and rattling to affect production performance. No

parts sticking or jamming in critical situations. These well insulated,

smooth running machines give you a precisely shrink wrapped package, run

all commercially available shrink films and provide energy savings

along with lower operating costs. What you get is a total performance

packaging system.

Performance Packaging

With over 40 years of manufacturing experience, Belco has learned

that your- framework for productivity and profitability relies upon many

important elements beyond the machine frame itself.

The welded steel box construction of the seal head is designed and

built to prevent flexing and misalignment during the constant, daily use

of the machine. This unique construction contributes to consistently

strong seals, long element wire life and years of trouble-free

performance.Each tunnel's carefully regulated air flow pattern assures

you constant uniformly shrink wrapped packages. Belco STCs can operate

at lower, more energy efficient temperatures, run at faster production

rates and make less demands on your work environment. No matter how

difficult your production schedule or what kind of film you choose, you

can depend on Belco STCs for maximum performance and optimum results.

Inside and out, from top to bottom, Belco creates a framework for

efficiency... a machine that pays for itself. Belco STCs feature:

variable speed conveyor control, top and bottom tunnel heat control,

constant or impulse heat sealing, adjustable impulse time and heat

adjust, element wire compensator, aluminum infeed tray with film opening

horn for easy product loading, adjustable height sealing table and a

sturdy film roll holder with unwind brake.

Popular STC options include: Magna-Lock seal arm hold down,

air-operated seal arm, power take-away conveyor and powered film unwind

with adjustable film inverting head. Various tunnel conveyor types are

available depending on your product and required packaging needs. Heavy

duty locking casters for portability and space conservation are

standard.

Strength of Product, Strength of Company

It's not surprising that the most dependable...and consequently,

most productive...packaging systems on the market are made by Belco

Packaging Systems, Inc. the largest manufacturer of shrink packaging and

blister sealing systems on the West Coast, Belco engineers every

product for long life and maximum productivity. All Belco machines are

backed by a quality service and repair network, a friendly,

knowledgeable staff that makes doing business so easy and one of the

most comprehensive warranties in the industry. Belco Packaging Systems,

Inc., the experts at developing complete packaging systems for your

specific requirements, is committed to your total satisfaction. No ifs, ands or bolts.

How to choose which Belco STC is right for you?

Which ever machine you choose, you can be confident that it will be productive and profitable for you!

| Model Number | Conveyor style | Conveyor Height (Inches) | Max Conveyor Speed (ft/min) | Tunnel Dimensions (inches) | Temp Control | Seal Area | Optional Air Requirements | Maximum Film Roll | Space Requirements (Inches) | Power Requirements | Ship Weight (lbs) | |||||||||

| --- | --- | --- | Belt | Rod | Wide | Long | High | --- | Long | Wide | CF/C | PSI | --- | Wide | Long | High | Volts | Amps | Phase | --- |

| STC"ECO" | Belt | 33 | 60 | n/a | 18 | 24 | 8 | F | 20 | 16 | N/A | N/A | 26" | 34 | 92 | 58 | 240 | 35 | 1 | 550 |

| STC2016 | Belt/Rod | 33 | 60 | 90 | 18 | 24 | 8 | F | 20 | 16 | .02 | 80 | 26" | 34 | 92 | 58 | 240 | 35 | 1 | 625 |

| STC2520 | Belt/Rod | 33-36 | 60 | 90 | 21 | 36 | 8 | F/C | 25 | 19 | .02 | 80 | 29" | 37 | 124 | 58 | 240 | 45 | 1 | 950 |